I’ve used rim plugs (“Veloplug” is a brand of rim plug) in 3 separate bike builds and they have been worthwhile as a rim tape / strip alternative.

Essentially, rim plugs are drawing pin sized bits of plastic that have a tub instead of a solid rod which you insert into the spoke holes from the inside of the wheel.

Their purpose is to protect inner tubes (squishy rubber things that hold air) from the inside of the rim bed; the rim bed contains spoke holes drilled by a wheel rim factory that have rough edges, which may puncture inner tubes.

Rim plugs are light, low maintenance, and are likely the safest option for lining a wheel. There are only 2 problems:

- very expensive (~£10 for a pack of 72, not including shipping)

- made specifically for rims of certain sizes (smaller wheels will have some trouble fitting normal rim plugs)

DIY-CAD for exact fit

Front wheel braking on the Moulton Mk 2 commuter bike was beginning to become a little loose due to rim wear. I already bought a replacement wheel (Brompton-size 16" - 37x249) and needed to plug the spoke holes. Previous attempts at using normal rim plugs were a little troublesome since the trim around the rim plug was larger than the width of the rim bed.

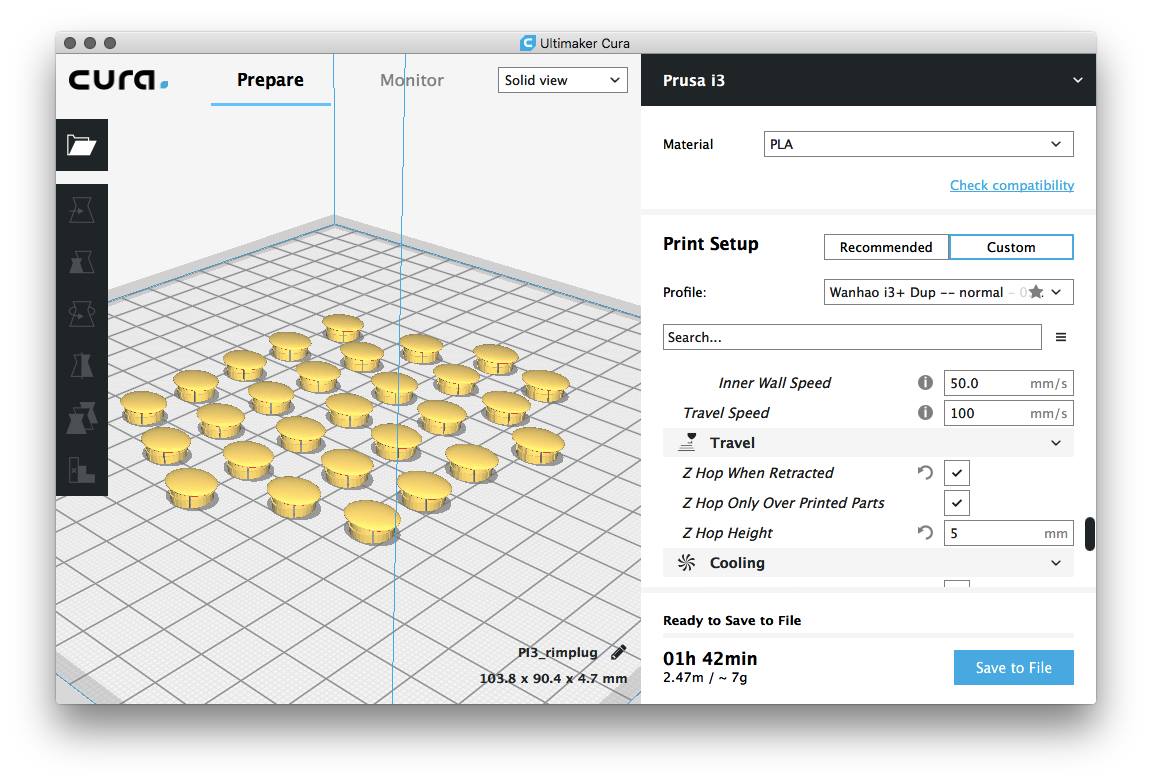

3D printing would solve the issue of fit as well as reduce cost to 0, and introduce an ever so small amount of weight savings, even over conventional rim plugs.

Whipping up a quick design and adjusting tolerances, I was able to get an exact fit within 2 iterations of trial and error. Though PLA plastic begins to deform at 60 degrees C, I wasn’t too worried since the rim itself is a heat sink and PLA is generally a heat insulator. Additionally, PLA’s UV sensitivity does not factor much in this application since the plugs will be completely sealed inside the wheel.

Testing period

The wheel has so far survived a few days worth of commutes with the front tire inflated to 90 PSI and a total distance of about 18km a day. I shall continue to note my findings here during the lifetime of these parts.